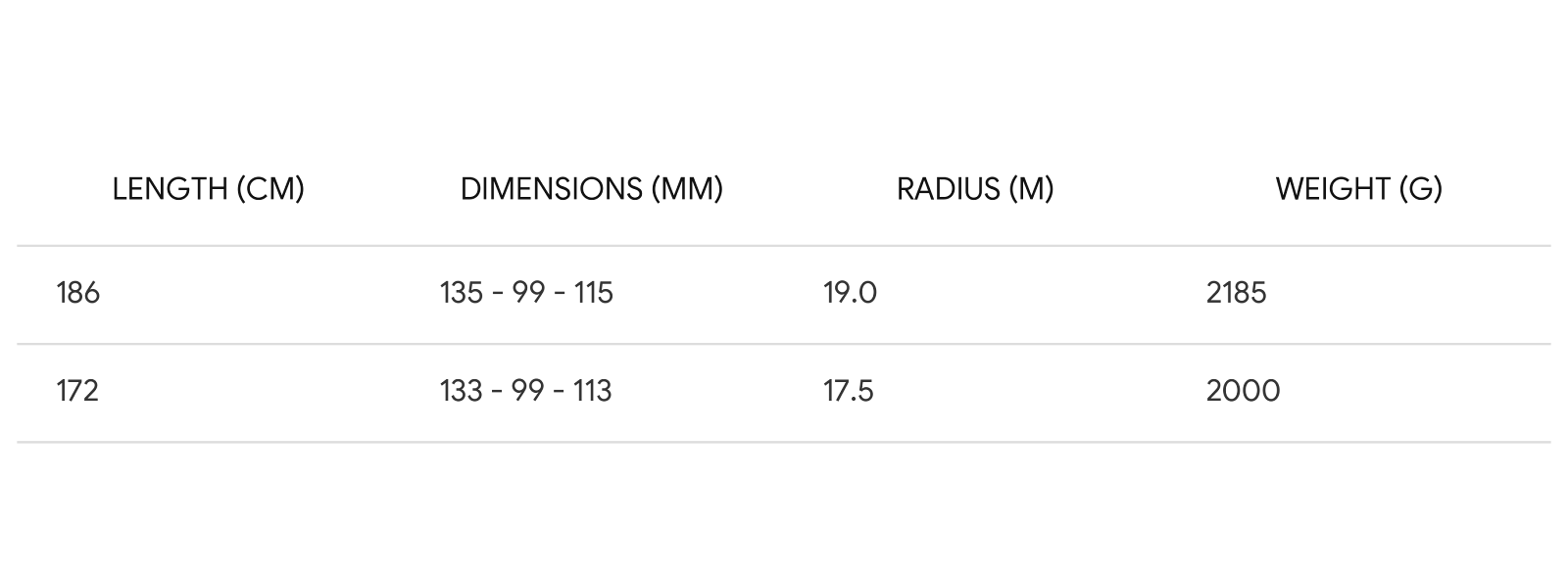

Specifications

The Art of Construction: Building Skis with Intention

Extra Thick Base and Edge

In our minds, the most sustainable thing we can do for a performance-oriented product that isn’t readily recyclable is to extend its lifespan. One of the ways we achieve this is by using a thicker-than-standard base and edge, effectively increasing the number of times the skis can be tuned/repaired before the end of their usable life.

Wood Core

Our core is comprised of an intentionally engineered combination of Ash and Poplar. We combined these two wood species to afford the skis the ideal strength-to-weight ratio to remain powerful enough to be stable at high speed, but light enough to remain playful at slow speed. The Ash Wood was intentionally placed to coincide with the mounting area for bulletproof binding retention, even for telemark skiers.

Re-Processed UHMW Sidewalls

By using re-processed UHMW sidewalls, we captured all of the performance benefits that come from using a virgin UHMW sidewall, such as impact, shock, and abrasion resistance, all while doing what we reasonably can to slow this material’s journey to a landfill. This is another design choice in alignment with our goal to extend the lifespan of our products by using high-performance materials while simultaneously incorporating the practice of circularity wherever reasonably possible.

Uni-directional Carbon Fiber

There are a lot of ski companies that use carbon “stringers” in their skis, and we believe that product makes no appreciable difference in ski performance and therefore amounts to a marketing gimmick; the carbon we use is different from these products. We intentionally engineered our skis to utilize a full-on unidirectional carbon weave, which adds a noticeable snap and support to the flex profile, all the while increasing the usable life of the skis by significantly increasing the amount of use required before there is a noticeable degradation in rebound performance.

Flax Fiber Dampening System

By incorporating intentionally-placed flax fiber into the composite layup, we reduced a constructive buildup of the resonant frequencies that cause the sensation commonly known as “chatter.” This design choice contributes to the skis’ ability to keep its composure in variable conditions at all speeds, all while not adding significant mass to the ski in the way a metal laminate would.

Triaxial Fiberglass

Through the intentional use of two layers of full-width triaxial fiberglass, we struck the perfect balance of longitudinal and torsional stiffness. The interplay of these two stiffness axes is part of the recipe that makes the skis stable at high speeds while remaining playful in their turn initiation qualities at slow speeds.

Bio-Based Epoxy Resin

With 30% bio-based content, we selected this product to use in our skis in alignment with our philosophy of incorporating circularity into our process wherever possible, while also increasing product lifespan.